By: Joshua Howgego

Send to a friend

The details you provide on this page will not be used to send unsolicited email, and will not be sold to a 3rd party. See privacy policy.

Last month, 92 countries met in Japan and signed the Minamata Convention, an agreement aiming to curb global mercury pollution. Once ratified, likely in around three years, the treaty will require countries to draw up plans for reducing their mercury emissions.

I spoke to Anthony Persaud, who handles policy and field operations at the Artisanal Gold Council, a Canadian organisation focused on the sustainable development of small-scale gold-mining communities in the developing world. I learned that there are several examples of low-tech equipment that mining companies in developing nations could use instead of mercury in gold-mining. But there are also many different types of company — with varying sizes and cultures — so governments’ reduction plans will need to take this into account, according to Persaud.

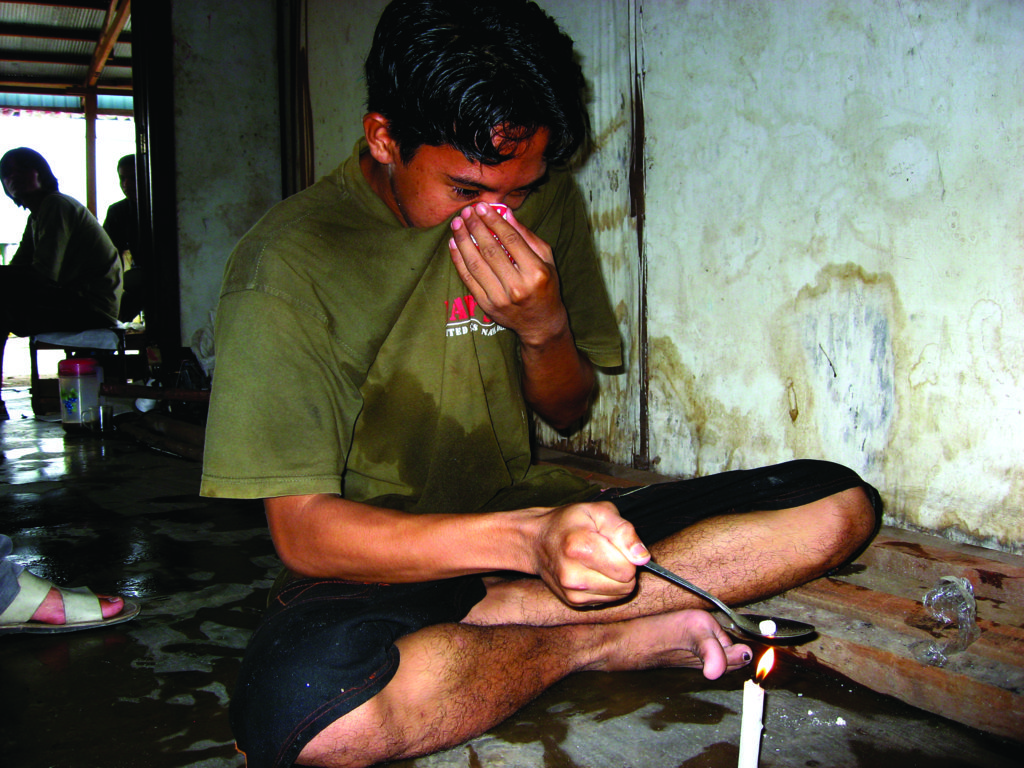

Tens of millions of the world’s poorest people make their living from gold-mining and most of them use mercury. The chemical forms an alloy with gold that can be quickly and easily filtered out in lumps from mined and ground rock. These lumps are heated to evaporate the mercury and leave purified gold. But toxic mercury vapours escape into the environment and workers’ lungs as a result — the convention’s goal is to cut these emissions.

Gold-mining occurs in many developing nations, but is particularly prevalent in North Africa and Latin America. In most countries where the industry is present, there are large, privately owned mining companies, Persaud says. But there are other business structures too. In Senegal, for example, there are so-called groupes d’interesse economique — collections of small mining companies that pool their efforts to gain competitive advantage over smaller-scale operations. And in Bolivia “cooperatives are the dominant model”, says Persaud.

“Every nation has a different range of gold-mining operations, each with varying cultures and financial resources,” says Persaud. But in nearly all cases miners often use mercury because it is a “cheap, quick, easy and accessible way of capturing the gold”, he says.

According to Persaud, working out other ways to increase gold concentration is the key to reducing mercury usage because this is essentially the job mercury does. The Artisanal Gold Council has jointly produced a report outlining seven simple technologies that can help concentrate out gold from mineral powders. [1] These all work on the principle of gravity — gold is heavier than most other minerals — and range from expensive centrifuges to cheaper ideas such as sluices, which separate heavier particles using water flowing down a channel (pictured below). With the gold pre-concentrated in the powdered rock, miners can use much less mercury in the final purification step.

Which technology is most appropriate for which company depends on several factors, says Persaud. For example, larger private companies might be able to afford more-effective devices such as centrifuges. It will also depend on the size of working parties, since certain technologies need several individuals to operate and so would be unsuitable for isolated workers.

“It’s vital for governments and other stakeholders to work closely with the individual mining operations to work out which of these technologies might be helpful to the mining businesses and operations that are prevalent in their countries,” says Persaud.

Joshua Howgego is SciDev.Net’s deputy news and opinions editor.

References

[1] Artisanal Gold Council and the UN Environment Programme A Practical Guide: Reducing Mercury Use in Artisanal and Small-Scale Gold Mining (UN Environment Programme, 2012)