Send to a friend

The details you provide on this page will not be used to send unsolicited email, and will not be sold to a 3rd party. See privacy policy.

One of the most puzzling paradoxes of the much lauded recent African growth is its bizarre matrix of high growth and high unemployment.

The low impact on poverty reduction and unemployment of the otherwise impressive growth has, in turn, been attributed to the low contribution of the manufacturing sector. Manufacturing has stagnated and contracted while the service sector continues to grow at a strong rate, leaving economists pondering whether Africa is undergoing a premature de-industrialisation. [1]

Africa is expected to benefit from more manufacturing jobs due to China’s rising wages and transition to high-value, high-skill manufacturing.

“Africa’s position as a preferred destination for low-wage jobs from Asia is now being undermined by the advent of 3D printing technology.”

Hailemichael Teshome Demissie, African Centre for Technology Studies (ACTS), Kenya

But the likelihood of attracting these jobs is likely to suffer setbacks as a result of the rapid rise of digital manufacturing, especially 3D printing.

The insourcing boom in developed countries should be disquieting for developing countries awaiting their manufacturing moment: it is a trend that marks the beginning of a reversal of the migration of jobs to low-wage regions.

In 2013, President Obama celebrated the return of manufacturing jobs back to the United States from Japan and Mexico by hailing 3D printing technology as offering the potential to resuscitate and revolutionise manufacturing in the country.

3D printing tech: description

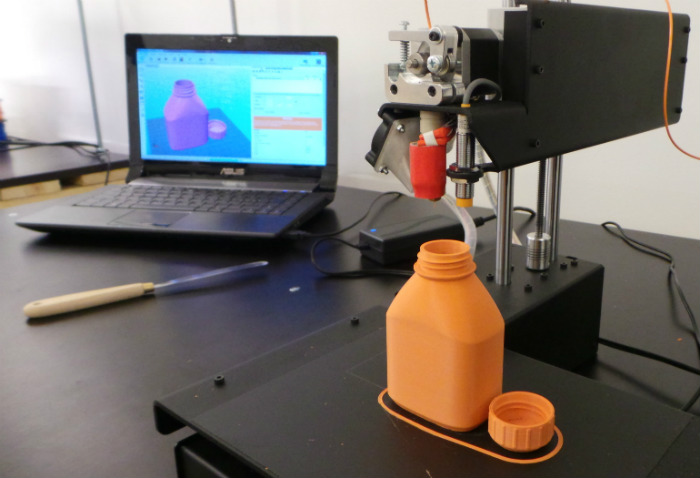

3D printing technology, also known as rapid prototyping, additive or digital manufacturing, has been around for at least the last three decades.

However, it is only in the last five years that it has come to widespread use in the manufacturing sector. 3D printers turn digital design data into a three-dimensional tangible, physical object.

Various materials and processes are being used to print solid 3D objects: plastic resins, metals, wood fibre, carbon fiber, construction waste, desert sand, human tissue and many others. New materials, methods and combinations of materials and methods are being introduced to perfect the technology.

Initially, 3D printing was used as a niche activity in big manufacturing firms that mainly used it to develop prototypes. The technology is invariably described as disruptive. For example, in one survey, respondents from industries and academic institutions said they expected 3D printing to be “the most disruptive technology” in the next three years.

Surveys carried out by global accounting firms such as PwC and Deloitte have shown a similar result concerning the disruptive potential of 3D printing technology, suggesting it could be on a level never seen before. [2,3]

The technology’s impacts

Africa is certainly to be impacted by the disruptions 3D printing technology is set to trigger. The continent’s position as a preferred destination for low-wage jobs from Asia is now being undermined by the advent of the technology, which can do manufacturing at a negligible cost, with little or no wage labour.

Of the 100 million jobs expected in developing countries as a result of China’s transition to high-value, high-skill manufacturing, Africa is to land none or very few.[4] The destination of these jobs remains unknown.

It is not another region with cheap labour that is thwarting Africa’s ambition to succeed China as the factory of the world. Rather, it is technology that promises to slash the cost of manufacturing to a “near zero marginal cost”.

“The opportunity to turn the towns and countries of Africa into centres of high-tech manufacturing needs to be seized with no less vigour than that shown in the developed world.”

Hailemichael Teshome Demissie, African Centre for Technology Studies (ACTS), Kenya

The exploitation of cheap labour can no longer serve as the comparative advantage in the face of the relatively cheap, yet highly efficient technology that is radically overhauling the manufacturing sector around the globe.

Even in the scenario where Chinese factories relocate to Africa, it is questionable whether these factories will be competitive (assuming that they will still have to incur considerable cost of labour).

Given the rapid obsolescence of conventional manufacturing models, it is also uncertain whether these factories will be sustainable in the short-run or the long-run.

What Africa should do

In order to remain economically competitive, Africa should accelerate the process of transitioning to high-value manufacturing by acquiring and developing capabilities in 3D printing technology. This transition cannot be realised by merely repeating what China has done, to relocate Chinese plants to Africa.

Calestous Juma, an expert in science and technology for development, draws attention away from advice that Africa should follow on China’s footsteps in the context of the rise of 3D printing technology. Instead, he argues that Africa should emulate Taiwan — that “the rise of 3D printing could do for Africa what semiconductors did for Taiwan in the 1960s”.

The fate of manufacturing in Africa is increasingly tied to emerging technologies, particularly 3D printing technology, that The Economist labelled as “the third industrial revolution”. Yet uptake of the technology has been slow and the discussion about its relevance and potential for African development is rather muted.

President Obama’s pledge to turn America’s ‘Rust Belt’ into a ‘Tech Belt’ deploying 3D printing technology is instructive for Africa too. The US government’s decision to open several 3D printing manufacturing hubs in a bid “to turn regions left behind by globalisation into global centres of high-tech jobs” is not only a precedent to emulate, but also a serious warning if Africa chooses to ignore it.

African countries should consider nine recommendations for harnessing 3D printing technology for sustainable development (see Below).

The opportunity to turn the towns and countries of Africa into centres of high-tech manufacturing needs to be seized with no less vigour than that shown in the developed world.

Box: Recommendations for Africa to use 3D printing tech for sustainable development |

|

1. Initiate and foster trans- and interdisciplinary collaboration in the development of additive manufacturing or 3D design and printing technology in Africa. 2. Create the innovation ecosystem for 3D printing technology by bringing together funding agencies, academic institutions, governments, non-governmental agencies, entrepreneurs, industries and research institutions. 3. Support the design and adoption of local, national, regional and continental policies, regulatory frameworks, guidelines and funding strategies to facilitate the adoption of the technology. 4. Support the development of 3D printing curriculum and its integration in existing engineering, materials science or other curriculums or its offering as an interdisciplinary stand-alone course at undergraduate and postgraduate levels. 5. Undertake innovative high-quality and internationally competitive research in collaboration with major national and international centres and research programs to help strengthen research and maintain and raise Africa's research excellence in additive or digital manufacturing research. 6. Support workforce development and the development of expert networks, R&D infrastructures through human resource development and acquisition of software and hardware. 7. Initiate and support start-up and spin-off companies and foster entrepreneurship creating technology jobs in the making and servicing of both the hardware and software tools of 3D printing technology. 8. Draw resources and expertise from governmental and non-governmental organisations, academic institutions, industries, international and regional funding agencies into a cooperative endeavour to keep abreast of the latest advances in additive manufacturing. 9. Monitor and create awareness about the state of the technology, its potential and the disruptive impacts with regard to African economies, drawing attention on how the disruptive innovation can be turned into an opportunity that contributes to national and regional renewal of the manufacturing sector and, ultimately, to socio-economic development in general. |

Hailemichael Teshome Demissie, PhD, is senior research fellow and program head, Inclusive Bioeconomy, African Centre for Technology Studies (ACTS), Nairobi, Kenya. He is also a member of the ACTS–KU (Kenyatta University) team tasked with the preparation for the establishment of the African Centre for Excellence in 3D Printing Technology. He can be reached at [email protected]

This piece was produced by SciDev.Net's Sub-Saharan Africa English desk.

References

[1] Dani Rodrik Premature deindustrialisation (National Bureau of Economic Research, February 2015)

[2] PwC 3D printing and the new shape of industrial manufacturing (PwC, June 2014)

[3] Benjamin Grynol Disruptive manufacturing: the effects of 3D printing (Deloite, nd)

[4] Justin Yifu Lin From flying geese to leading dragons: new opportunities and strategies for structural transformation in developing countries (World Bank Group, June 2011)