Send to a friend

The details you provide on this page will not be used to send unsolicited email, and will not be sold to a 3rd party. See privacy policy.

A simple but super-absorbent artificial sponge could lower the cost of cleaning up crude oil spills in developing countries.

A team of researchers, based at the Italian Institute of Technology in Genoa, found that simple sponges made from polyurethane foam soaked up oil spills better than more expensive sponges treated with nanoparticles.

They discovered that polyurethane foam with pores of less than half a millimetre can soak up as much as 30 grams of oil per gram of sponge. This is three times as much as sponges made from treated polypropylene, which are normally used to mop up oil spills.

“We decided to show the importance of the actual structure of the foams that are used to recover spilled oil from water,” says Javier Pinto, the lead author of a paper on the study, published in the Journal of Physics D: Applied Physics on 1 March.

Moreover, the team demonstrated that almost all the oil can be recovered by simply squeezing the sponge, which can be reused at least ten times.

Synthetic sponges used to mop up oil are commonly treated with nanoparticles or through complicated chemical procedures. Such methods allow them to soak up more oil, for example by ensuring they absorb no water.

“These kind of treatments are not really necessary to achieve the maximum oil absorption capacity,” says Pinto.

The results could soon change how oil spills are dealt with, especially in the developing world, says Michel Boufadel, an environmental engineer at the New Jersey Institute of Technology in the United States. “The main advantage of this study is that the foams suck oil in rather than relying on fancy chemical treatments to absorb it,” he explains.

This not only cuts production costs, it also avoids potential added pollution from the chemical treatments, he says.

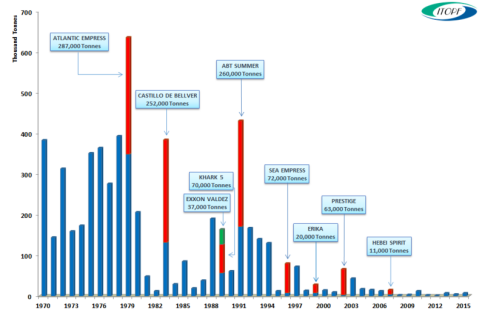

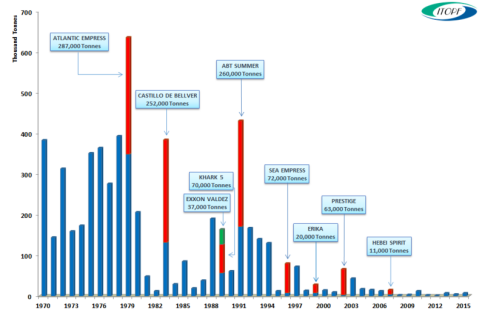

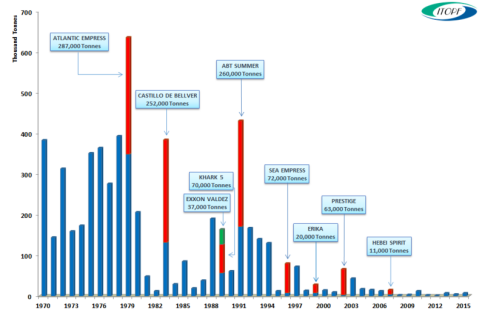

Total global oil releases into environment from medium and large spills (including names of major spills)

According to the International Tanker Owners Pollution Federation, around 7,000 tonnes of oil was spilled into the sea in 2015 — often by ships in developing countries where regulation around oil disposal is less strict or not enforced. Oil spills can harm or kill wildlife and can take years to clean up, costing governments around US$18 per gallon of spilled oil and devastating income sources such as tourism and fisheries.

“Once we can show that our polyurethane foams are more economic and competitive compared to other materials, we’ll be able to convince the industry to use them as a reliable option in the remediation of these disasters,” Pinto says.References

Javier Pinto and others Effect of the porous structure of polymer foams on the remediation of oil spills (Journal of Physics D: Applied Physics, 1 March 2016)